Imagine a world where every physical entity—living or non-living, from a human to an X-ray machine to an entire city—can have a digital counterpart that can be analyzed, tested, and optimized in real time.

Sounds equally scary as well as exciting, doesn’t it? Well, it’s not science fiction, but the reality in the making, as promised by the evolving digital twin technology, which is shaping the future across industries—from aviation and automotive engineering to medicine and manufacturing.

Digital twins represent one of the most transformative shifts in modern technology. While traditional simulation creates a model, digital twins create a living, evolving digital counterpart to a physical system, process, or entity. They move beyond “What if?” scenarios into “What is happening now, and what is likely to happen next?”

A study by Gartner says that by 2027, over 40 per cent of large companies worldwide will be using digital twin technology in their projects to increase revenue. Also, according to a report by Marketsandmarkets Research, “The global digital twin market is expected to grow from USD 21.14 billion in 2025 to USD 149.81 billion in 2030 at a CAGR of 47.9% over the forecast period.”

In this blog, we will explore what digital twins truly are, how they differ from traditional simulations, why industries—especially healthcare—are rapidly adopting them, and how they unlock value far beyond what simulation alone can offer.

What Exactly Is a Digital Twin?

In simple words, a digital twin is a virtual replica of physical systems, objects, persons, or processes. It’s not a traditional 3D model but a live digital entity fed by real-time data that mirrors the behavior and condition of its physical counterpart, making it possible to simulate, predict, and optimize outcomes before they happen in the real world.

Digital twin is a leading-edge technology that mirrors almost every aspect of a product, process, person, or service and has the potential to replicate everything in the physical world in the digital space and in turn provide feedback from the virtual world. This process enables real-time detection of anomalies and resolution of physical problems, design faults and others, and helps to build better solutions and realize value and benefits faster than was previously possible.

Traditional simulation runs on assumptions or static data. Contrarily, a digital twin is driven by real-time data extracted from physical objects, persons, systems, processes, or environments, which is dynamically connected to its physical counterparts through:

- Live sensor data

- Historical datasets

- Predictive analytics

- Continuous feedback loops

- AI and machine learning models

These capabilities allow the digital twin to evolve alongside the physical object, making it a continuously learning system.

Digital Twin Components

There are three components to digital twins:

- Physical Entity: Human (e.g., patient, staff), machine (e.g., X-ray machine), ecosystem (hospital unit), supply chain, or device (e.g., medical-grade biosensors and Patches)

- Digital Representation: A software-based virtual replica (the digital twin) of the physical entity’s structure and behavior.

- Data Exchange Loop: A two-way flow of real-time and historical data that updates the twin continuously.

Together, it makes the twin not just a reflection but a live replica with a predictive intelligence layer that evolves with experience.

Traditional Simulation vs. Digital Twin: Why the Difference Matters

It becomes imperative to differentiate digital twins from traditional simulation to truly understand the potential of the former. Consult the table below:

| Aspect | Traditional Simulation | Digital Twins |

|---|---|---|

| Static vs. Dynamic Data | Uses predetermined inputs and static assumptions; the model does not change after the run. | Continuously updated with real-time data, the model “lives” alongside the system it represents. |

| One-time Scenario vs. Lifecycle Monitoring | Useful for testing a few scenarios, typically during the design or training phase. | Provides insights throughout the lifecycle—from design and operation to maintenance and optimization. |

| Limited Insight vs. Predictive Capability | Predicts outcomes based on hypothetical conditions. | Learns from real data, predicts failures, optimizes performance, and improves decision-making. |

| Theory vs. Reality | Helps answer “What if this happened?” | Helps answer “What is happening, why, and what will happen next?” |

How Digital Twins go Beyond Traditional Simulation

As was discussed before, digital twins feed on a steady flow of real-time data, and this lets them go beyond traditional simulation models in the following aspects:

- Real-time Monitoring

- Real-time visualization

- Automated alerts

- Continuous performance tracking

- Immediate response to anomalies

Digital twins are continuously linked to sensors, systems, and devices. This real-time connection allows:

Simulations cannot replicate real-world dynamics in this way.

- Predictive and Prescriptive Analytics

- Predictive analytics: What is likely to happen?

- Prescriptive analytics: What should be done to prevent or optimize outcomes?

Digital twins use AI and machine learning to go from prediction to prescription:

This allows industries to reduce risk, prevent failures, and improve outcomes with unprecedented accuracy.

- Personalized Delivery

- Individual patients

- Specific machines

- Unique hospital workflows

- Personalized supply chain behavior

Simulation models are usually generic.

Digital twins, however, can represent:

This level of personalization leads to precise and context-specific insights.

- Support Continuous Learning

Simulations remain static unless manually updated, whereas digital twins evolve as they receive more data and become more accurate.

- Closed-Loop Feedback

The closed-loop feedback mechanism of digital twins lets it not just analyze but act. For example, a digital twin of a hospital ICU can adjust ventilation systems or staffing models automatically based on real-time demand.

This closed-loop automation is impossible with static simulations.

Why do Digital Twins Matter?

Having looked at how digital twins take the concept of simulation beyond the traditional means in more ways than one, let’s look at some of its significant benefits:

- Predictive Maintenance and Efficiency: Predictive maintenance is one of the most impactful and immediate paybacks of digital twins. The continuous monitoring of equipment and the use of historical data enable organizations to anticipate failures, thereby reducing downtime and extending the life of their assets. This isn’t just about fixing things before they break; it’s about optimizing performance every step of the way.

- Enhanced Decision-Making: Integration of data from various sources, like sensors, cameras, ERP systems, and more, empowers digital twins to provide a unified view of operations. This holistic approach to data enables faster, more accurate decision-making at every level.

- Accelerated Innovation: Digital twins provide a simulated environment which is a replica of the natural environment where you can test a new product design or process before implementing it in the real world. This reduces risk, saves time, and lowers costs, which is a game-changer for R&D teams.

- Sustainability and Smart Resource Use: Organizations can make use of digital twins to track energy usage, emissions, and resource consumption in real time. By identifying inefficiencies, organizations can take smarter, greener decisions. In buildings, for instance, digital twins can optimize HVAC systems, lighting, and occupancy for both comfort and carbon savings.

- Resilience in a Complex World: Resilience is the key in uncertain times. Digital twins allow organizations to run “what-if” scenarios and stress tests, helping them prepare for disruptions, whether it’s supply chain bottlenecks, equipment failures, or climate events.

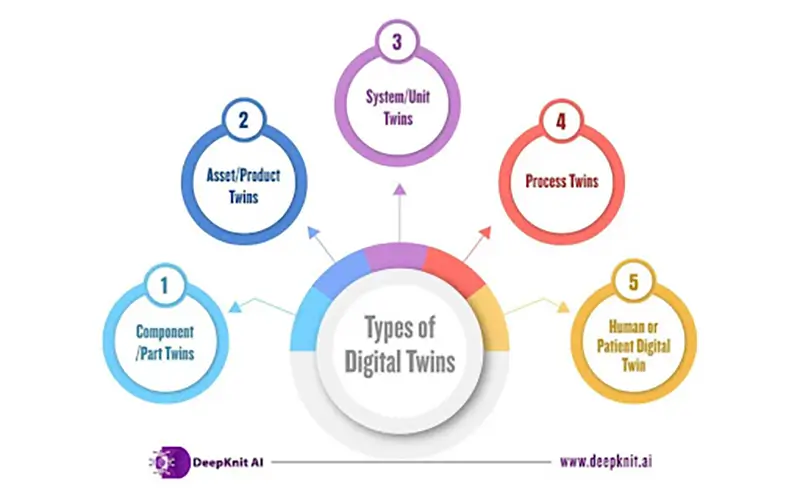

Types of Digital Twins

Digital twins come in different forms depending on complexity and purpose:

- Component/Part Twins: This is the most basic type of digital twin, representing an individual component or part within a larger system. Examples include sensors, valves, switches, etc.

- Asset/Product Twins: This is the second level of digital twin, consisting of different components or parts interconnected to form an entire device or machine, like an MRI scanner or ventilator.

- System/Unit Twins: These digital twins integrate multiple asset twins to model how entire systems operate together in real-time. Represent entire facilities like hospitals, manufacturing lines, or transportation hubs.

- Process Twins: The process twin is the most comprehensive type, representing entire workflows often spanning across multiple departments or facilities. If system twins model one section of a hospital, like the emergency room, process twins oversee the operation of the entire hospital, from outpatient appointments to staff scheduling to inventory management in the pharmacy and what not?

- Human or Patient Digital Twin: This is one of the most advanced forms, used in healthcare to model the entire physiology of individual patients.

This layered ecosystem helps organizations create a complete digital landscape of their environment.

How Digital Twins are Transforming Healthcare Systems

It would be right to say that healthcare is one of the industries that benefited most from digital twins because of its complexity and data intensity. The availability of electronic health records (EHRs), remote monitoring devices, wearables, smart medical equipment, and AI-driven insights makes healthcare an ideal platform for digital twin innovation.

Below are key areas where healthcare digital twins go far beyond traditional simulation:

- Patient Digital Twin

Traditional simulations help train clinicians, but they cannot replicate the nuances of an individual patient.

Digital twins create personalized models based on:

- Real-time vitals

- Imaging data

- Lab results

- Medical history

- Genomics and lifestyle data

This enables:

- Tailored treatment plans

- Predictive risk assessments

- Virtual testing of therapies

- Early detection of deterioration

Clinicians can run multiple treatment simulations on the twin before choosing the safest approach for the patient.

- Hospital Operations Digital Twin

Hospitals struggle with resource constraints, unpredictable patient flow, and emergency surges.

A digital twin of the hospital provides:

- Real-time bed availability

- Operating room scheduling optimization

- Staff workload prediction

- Supply chain visibility

- Infection spread modeling

Unlike traditional simulation, which is used for planning, digital twins support operational decision-making every hour.

- Medical Device Performance and Maintenance

Healthcare digital twins monitor devices such as imaging equipment, infusion pumps, and ventilators.

They provide insights into:

- Wear and tear

- Performance anomalies

- Maintenance needs

- Failure predictions

This improves uptime, patient safety, and long-term equipment performance.

- Surgical Planning and Robotics

Surgeons can use digital twins to create personalized pre-operative plans based on the patient’s anatomy.

AI-driven twins can simulate:

- Surgical outcomes

- Tissue response

- Bleeding risk

- Recovery timelines

Robotic systems linked to twins improve precision and patient outcomes.

- Population Health and Public Health Planning

Population-level digital twins help predict:

- Disease outbreaks

- Hospitalization trends

- Resource needs

- Impact of public health policies

This allows governments and institutions to make smarter, data-backed decisions.

Benefits of Digital Twins Across Industries

While healthcare is a major beneficiary, digital twins transform many other sectors:

Manufacturing

- Reduced downtime

- Predictive maintenance

- Quality optimization

- Production line efficiency

Automotive and Aerospace

- Real-time vehicle performance

- Autonomous vehicle training

- Simulation of wear patterns

- Faster prototyping

Smart Cities

- Energy optimization

- Traffic flow improvement

- Waste management automation

Energy and Utilities

- Grid demand forecasting

- Asset life-cycle management

- Outage prediction

The consistent theme across industries: Digital twins extract insights from virtual replica of physical systems and turn them into meaningful actions.

Challenges in Implementing Digital Twins

Despite their benefits, digital twin adoption comes with challenges that must be addressed.

- Interoperability Issues

For twins to function, they must integrate data from:

- EHRs or ERP systems

- Sensors and IoT devices

- Imaging systems

- Cloud platforms

- Third-party databases

- Fragmented systems limit the twin’s capabilities.

- Data Quality and Integration

- Poor or incomplete data leads to inaccurate predictions.

- Data cleaning and transformation are essential.

- Scalability and Computational Costs

- Complex twins—especially human twins—require significant computing power.

- Cybersecurity and Privacy Concerns

- Real-time, sensitive data must be protected with strong security frameworks and compliance protocols.

- Change Management

- Digital twin adoption requires cultural, process, and workflow changes across the organization.

Future of Digital Twin Technology in Healthcare

The digital twin technology is evolving rapidly. Over the next five years, expect to see:

- Deep AI Integration

AI will enable smarter predictions, autonomous decisions, and faster simulations.

- Hyper-Personalized Healthcare

A patient digital twin will guide personalized treatment plans, from chronic disease management to precision surgery.

- Widespread Use in Smart Hospitals

A hospital operations digital twin will provide dashboards for real-time decision-making.

- Real-Time Behavioral and Environmental Modeling

Digital twins will incorporate human behavior, social determinants, and environmental factors.

- Integrated Multiscale Twins

- Organ twins

- Cell twins

- Device twins

- Hospital system twins

Human twins will connect with:

Creating an interconnected health ecosystem.

Conclusion

The digital twin technology is already creating waves in industries like manufacturing and aerospace, and the next area of promise is healthcare due to its potential for real-time patient monitoring and predictive analytics. By integrating data from various sources, digital twins can provide real-time insights, forecast patient outcomes, and optimize hospital operations, making them critical for the future of healthcare.

However, the effectiveness of healthcare digital twins relies on two main factors: seamless interoperability with systems such as EHRs, wearables, and medical devices, and the integration of advanced AI capabilities. Additionally, strong AI capabilities are needed to extract meaningful insights and make informed decisions. Without these, the real purpose of digital twins in healthcare would be lost in translation.

DeepKnit AI addresses these challenges by offering expertise in AI, data integration, and healthcare systems, enabling organizations to create powerful digital twin ecosystems. With solid experience in AI, data integration, and healthcare systems, DeepKnit AI enables organizations to create powerful, connected digital twin ecosystems that truly add value.

As digital twins develop, organizations that invest in robust data and AI foundations will lead the way in innovations such as personalized medicine and predictive healthcare management.

From Digital Replicas to Real-world Impact.

Bring the Power of Digital Twins to Healthcare.

Reach a DK expert